I fixed my son's tenor saxophone today and I'm maybe a little more pleased with myself than I should be, but yeah!

Two of his valves weren't working because it got bashed by a snare drum last night in a crowded band room. He tried bending a lever back to get it to work, but had limited success. I couldn't even see what was broken. We planned to just rent a sax for a month or two while the repair guy kept it in his shop. It would be a couple hundred bucks but at least I could be sure a pro would do it right. My son would have none of it though. He ran down into the shop to get my screwdriver set, so that motivated my to get involved in the repair before he broke the thing even worse.

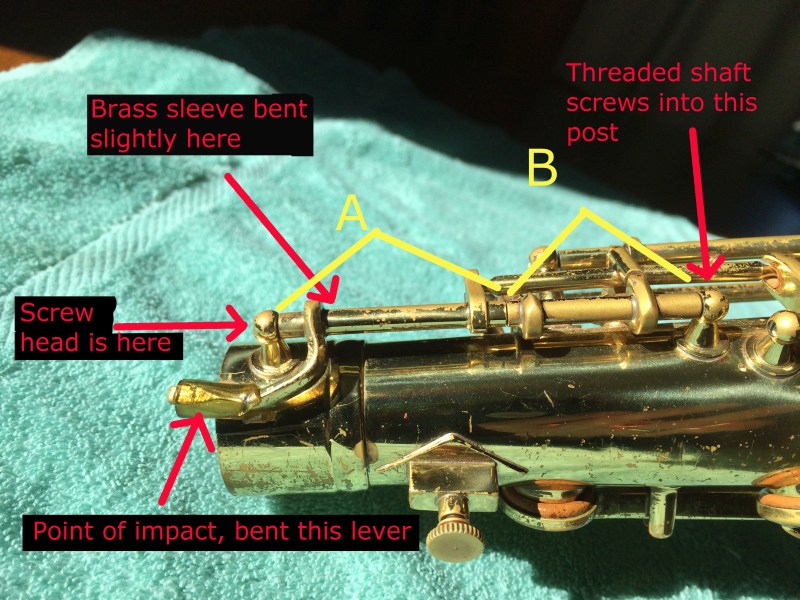

So this is the deal. There is a little steel shaft, maybe stainless steel, even, that goes between two posts welded to the sax. It's basically a screw. The threads screw into the post on the right, and the shaft has a head like a screw over to the left. Two brass sleeves fit over this particular shaft, and various levers and pads are welded to the sleeves. The snare drum hit the lever on the end there and bent it back a little bit. This made it no longer work the valve on the mouthpiece. Then the force was also transmitted to the sleeve and bent sleeve A so imperceptibly that you can't even see it in the picture. You could feel, though, that the sleeve was jammed and wouldn't allow a couple other valves to open.

So I carefully unscrewed the shaft holding these two sleeves, and removed the sleeves. Once I had them off, I could easily feel where sleeve A was bent by sliding the shaft in and out until there was resistance. I wanted to bend it straight again, but brass is very soft and brittle, and I was terrified of breaking or kinking the sleeve. So I found a drill bit with the same diameter as the sleeve and drilled a hole in a little block of maple. I went to my BAND SAW and cut through that drilled hole. This gave me nice firm supporting pads for the jaws of my vise. I clamped the sleeve carefully just below the bend, and bent it straight with my fingers. I would bend it incrementally, and then test it by trying to slide the shaft back into it and feel if it would bind up.

Anyway, that's all a little long winded, but the end result was that I totally fixed it. It all fits together nicely and the levers and valves just work smoothly. It took about as much time as driving to the music store to rent a new sax.